SINOPED Empty Hard Capsule Shell Making Machine Production Line Manufacture

Capsule production line complete assembly———————Without Chain

Main parameters of equipment

| model | SN-6 |

| volume | 1.8 million to 2 million per day |

| brand | Sinoped |

| Capsule size | #00,#0,#1,#2,#3,#4,#5 |

| Track length | 9.2m |

| HVAC system temperature control | 0.5 degree |

| handpiece | Temperature: 20 ℃ Humidity: 50% – 60% |

| Number of air changes | At least 40 pcs/min |

| Pure water system capacity | 0.5 t/h |

Installation display

Product Solutions

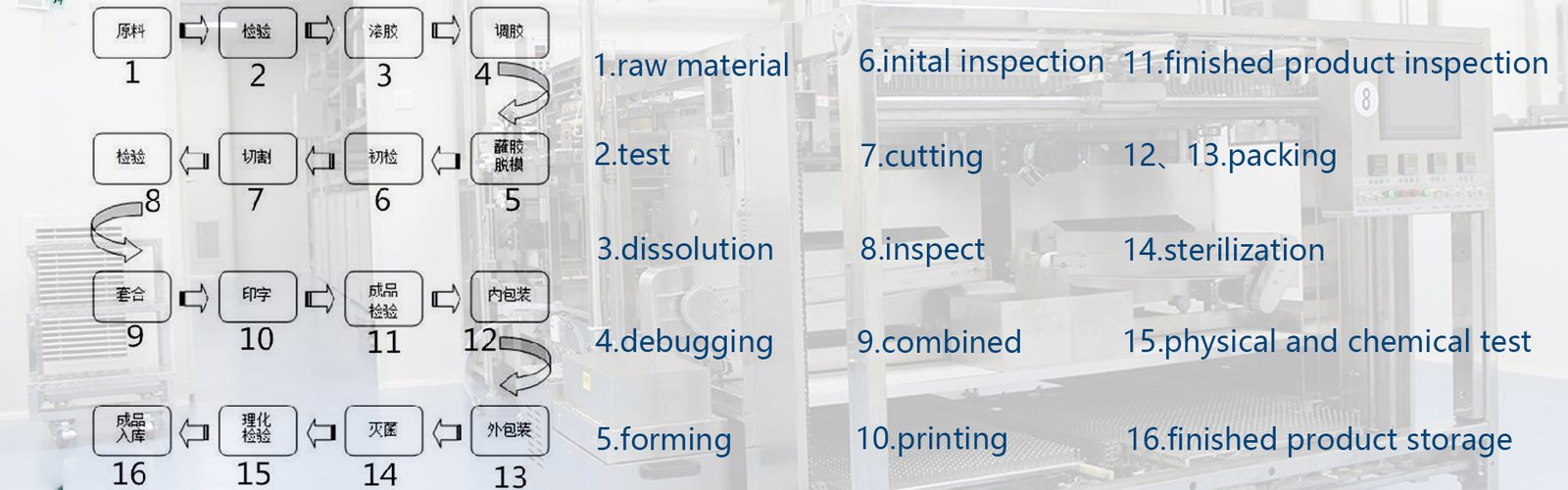

For empty hard capsule shell making machine production line,we help customer provide perfect solution,the process as below:

Main unit

The capsule production line is centrally controlled by PLC and mechanically driven by a motor. It integrates six processes including oiling, plate feeding, glue dipping, plate turning and shaping, drying, and automatic capsule extraction.

Polishing Machine

Polish the qualified empty capsules after inspection, usually adding dodecyl.

Vibrate screen

Conduct vibration screening for empty capsules, unqualified products will be recycled, and qualified products will enter the cutting machine through the pipeline.

Main unit

The capsule production line is centrally controlled by PLC and mechanically driven by a motor. It integrates six processes including oiling, plate feeding, glue dipping, plate turning and shaping, drying, and automatic capsule extraction.

Combine Machine

The finished cut body and cap are combined to obtain an empty capsule.

Automatic Light Inspection Machine

It is used to inspect empty capsule shell wether has hole,chips,cracks,etc defects.

Inner Package Room:

The polished capsules shall be wrapped inside, and ethylene oxide gas shall be added inside for sterilization, and then they shall be left in the outer packaging room for 7 days.

Hard capsule shell production line flow chart

We can produce capsules of all kinds of materials

Gelatin capsule\ Stomach soluble capsule\ Plant capsule\ Muslim capsuleEnteric capsule

Why choose Sinoped as your partner?

About us

Processing and packaging to create a better life – this is the daily work of our employees. Reviewing 16 years of experience, intelligent, innovative and reliable solution portfolio helps customers in the global pharmaceutical and food industries improve people’s lives.

Sinoped has 1100 service experts and a comprehensive service portfolio, covering the entire machine life cycle from spare parts management to digital production line optimization, laying the foundation for the smooth production process of all customers.

Years of experience

Patents and patent applications

Machines installed around the world

place

One-stop service

Expert services

We support you throughout the machine life cycle, from spare parts management to digital production line optimization. Service agreements are key elements of our product portfolio structure. We can customize our solutions according to your personal needs.

Our global network of experts supports you through maintenance planning, technical support and modernization, as well as operator training and retirement services. With our digital solutions, you can control the production process and achieve the transparency of product and machine data anytime and anywhere.

Contact us

If you have any needs or questions, please contact us. We will provide you with 24-hour online services and solutions.

Are you a factory or a trading company?

We are manufacturers and have worked in the industry for more than ten years.

What is your business service?

1. Sinoped provides a one-stop service (pre-sale, production, packaging, and after-sales). We have an independent R&D and Design team to help customers solve their pre-sales problems.

2. At the same time, we will combine our equipment to demonstrate to customers on-site. During the production of the equipment, we will constantly contact customers and reconfirm the inquiry.

3. After the machine completes production, we will show it to the customer for final confirmation. For packaging, we will adopt The interior of the standard wooden box will also be waterproof.

How is your company's after-sales service?

For after-sales service, when manufacturing defects (excluding fragile parts) are found during normal operation within the warranty period, Sinoped provides free parts and parts delivery. We will arrange for engineers to answer customers’ installation, commissioning,g, and other questions. If necessary, we will arrange online videos to guide customers, and translators will also arrange customers’ Better understanding.

Do you have quality assurance?

Yes, we provide a one-year quality assurance under normal circumstances, and we will provide new customers with Additional spare parts. At present, if we buy our equipment in bulk, we will have a 2-3 year warranty.

Can you make products with our brand?

Of course, we welcome cooperation as OEM service.